About Filtalloy Technology Limited

Filtalloy is an advanced metal mesh and filter elements manufacturer & supplier, with more than 20 years of experience. We have introduced the state of art machines and employed experienced technicians to supply high-performance, innovative materials, and solutions for applications in filtration and separation. Our products include:

丨Sintered Metal Filter

丨Sintered Filter Plates

丨Sintered Powder Filter

丨Hot Gas Filtration

丨Polymer Filter Element

丨Pleated Metal Filter

丨V Wire Filter

丨Leaf Filter

丨SPL Filter

丨Exturder Screen

丨Woven Mesh Filter

丨Perforated Sheets

丨Perforated Tubes

丨Perforated Strainers

丨Knitted Mesh Rolls

丨Compressed Knitted Mesh

丨Knitted Panel Filter

丨Demister Pads

丨SS, Copper & Brass Woven Mesh

丨Special Alloy Woven Mesh

丨Expanded Mesh

丨Etched Metal

Our products are widely used in numerous industries including aerospace, oil and gas, petrochemical, water, mine, polymer, food & beverage, automotive, and many other filtration and separation industries. With so many applications, we have built the R&D, design, machining, sales, and quality control departments. With the design and tailored solutions, we then translate them into high-level products. And our team has been learning about the forefront of filtration technology from industrial leading companies. Here customers could get high-quality products at an economic price!

MISSION

丨

Focusing on customers’ requirements, our mission is to continuously improve our technique, and provide customers with the optimal filtration solution and best services. Our solution is reducing cost by improving efficiency, shortening the production period, delivering stock goods soon, and so on.

VISION

丨

Our vision is to make the world much safer, healthier, and cleaner with our filtration and separation products. To fulfill this aim, we are willing to improve ourselves and overcome each difficulty. That drives us. Many customers choose to cooperate with us because we are a professional and reliable partner. To go further, we’ll continuously pay more attention to technique and machine.

Why Choose Us?

High Flexibility

With support from the professional technical department, our staff works with clients to identify the best filter element type and adapt alloy material for their application/requirements.

Rich Experience

Our skilled production team helps to make your prototype come real. With over 20 years of experience, we have the confidence to supply customized products that meet and exceed your product requirements.

Cost Analysis

In many cases the lowest cost product may backfire and really cost you more in the end, we will provide our customers with different choices and do a cost analysis to find the most cost-effective one.

First-class Customer Service

With support from our technical department, our sales team gives a quick turnabout and first-class service as we will learn more about your needs and share more info with you.

Quality Control

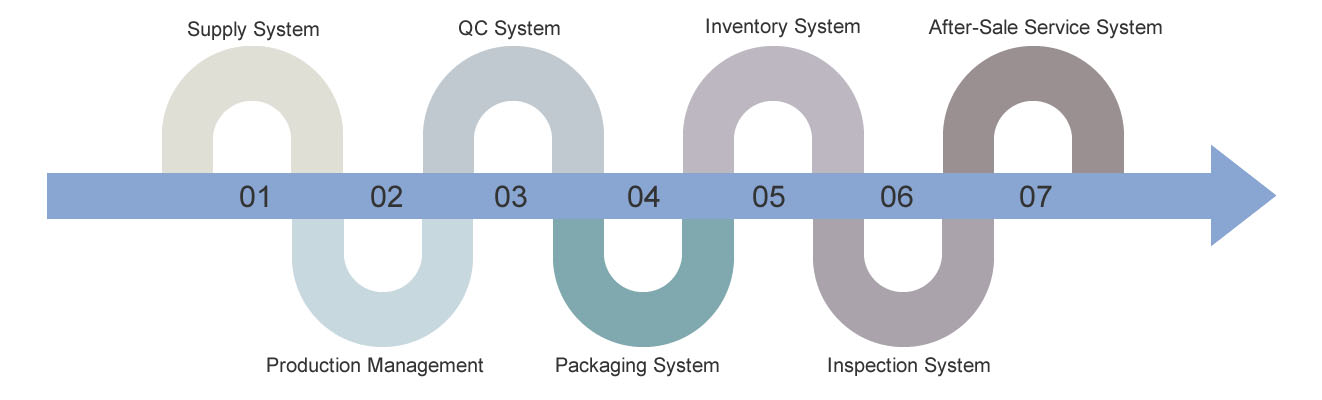

Every aspect of the quality control circle is concerned, from the supply chain, production management, QC system, packing, inventory system, inspection, and after-sales services.

Application Engineering

We pay high interest to new applications for our products. Welcome to consult, we will help to suggest from the tech and production aspect, and let’s develop your idea together.

Certificate

All our products are tested by our test team before shipment. To meet different requirements of our clients, we can find a third party to test and issue the SGS certificate.

Stock Availability

We have rich stock of woven wire mesh, the material ranges from SS304. SS316, SS316L, brass, copper, bronze to special alloy such as nickel, titanium, Hastelloy, Inconel, Monel, etc.

Quality Control

Quality is the most important thing. FILTALLOY is dedicated to supplying the products to satisfy and exceed customer commitment by continuously improving our technique, machine, process, and management. Below is the detailed quality control circle we use to ensure our products are satisfying to clients.

All our metal raw material is purchased from the largest metal company in China, we do a material content test using handy-alloy analysis equipment to ensure the material meets our client’s needs.

In each production process step, there is a staff who is responsible and will do random tests often. And our mesh products are produced according to ISO and ASTM standards.

Raw material and half-finished / finished products are put separately in the clean, dry warehouse to ensure the

goods will not be damaged or polluted even in the rainy season.

Set up a service center to solve after-sale problems, we try to find solutions for every customer to reach 100% satisfaction and record from the system to avoid similar problems basically.

With professional worker process and safety training before starting work, and the entire production process is strictly controlled to ensure product quality, operation safety under high efficiency.

Wrapped with waterproof paper or bubbled film to protect filter elements from damage during shipment, then put into the wooden case with high feet for easy transportation using the forklift.

For each product bath, we do a careful test on metal material chemical content, thickness, width, length, and other detail sizes. And we will take pictures and send them to our customers.

If you are interested in our products, welcome to contact us immediately to get information and best quote. If you have no idea about what you are looking for, we are at your disposal to work with you to find solutions together. Contact us

Would You Like More Information?

Filtalloy Technology Limited creates high efficent filtration solutions containing sintered filter, perforated filters, wire mesh filters and specific filters customized according to clients’ request.

Welcome to contact us and we will answer you asap. Thank you!