Sintered Mesh Filter with Higher Strength to Resist High Pressure Drop and Uniform Pore Size to Avoid Particles Escaping

Sintered mesh filter, also named diffusion bonded metal wire mesh filter, sintered filter, is popular in the industries of catalyst recovery, pharmaceutical refinery, gas filter and so on. It’s mainly used in the places where there high temperature or high pressure requirements are needed.

Sintered mesh filter is consisted of 2 – 5 multi layers of wire mesh layers. Fine layer is for filter, Corses layers for division and support. The coarse layer can also be replaced by perforated (punching) sheet, which has higher strength for higher pressure drop situation. Usual thickness is 1.7mm. Other thickness are also available. Pls order the sintered mesh filter according to your demand.

If you don’t know what kind of sintered mesh filter is siutable for you, pls contact us. We have rich experience to help you match it.

Advantages:

- Uniform filtering size

- The integrated structure is steady, not easy to deform

- High pressure resistance, up to 3000PSI differential pressure

- Heat resistance, up to 480℃

- Highly corrosive. Our product could work very well at sea water. We choose the suitable material to help customer solve corrosive problem

- Easy to wash by high pressure jet washer, brushing, steam and so on

- Auto self cleaning, shorten the equipment maintenance and shutdown time

Application of sintered filter element:

- Pharmaceutic: API production, catalyst recovery, refining filter, nutsche filter, ANFD filter etc

- Fabric: polymers, pigment, monomer etc

- Chemical: Herbicides, Pesticides, chromatography frits, resin trap

- Energy: LNG gas, ion-exchange resin, petro refining, circulating coolant, etc

- Coal industry, such as centrifuge

- Waste water treatment

- Pulp & paper bleaching

Specifications:

- Material: SS304/316/316L, also Alloy ( Hastalloy, Inconel 600 and 625, Monel, Titanium, Duplex and so on)

- Filtration: 2um-300um

- Different adaptor, such as 222, 226, BSPP, NPT and other customized kind

- Types: plate types and cartridge types

- Plate Size: 500×1000mm, 600×1200mm, 1000×1000mm, 1200×1500mm not welding Other sizes could also be customized

- Cartridges also available in different diameters and lengths to be applied in high pressure environments.

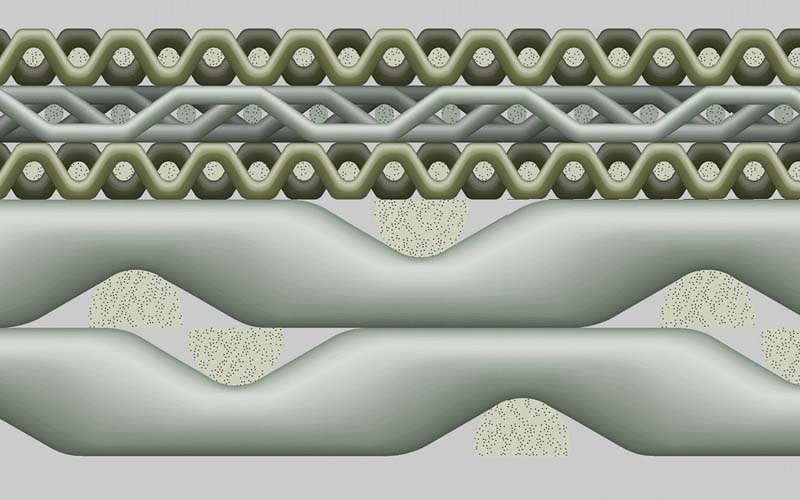

Top view of five-layer sintered mesh

Five layer sintered mesh has robust strength to resist high pressure drop.

Cross section drawing of five-layer sintered mesh

Five-layer sintered mesh with increased strength & protection on filter layer

| Standard Sintered Wire Mesh Data Sheet of Five-Layer Sintered Mesh | |||||

| Model | Nominal Rating | Structure | Thickness | Air Permeability | Bubble Point Pressure |

| μm | mm | l/min/cm2 | mmH20 | ||

| SMF5-1 | 1 | 200+400×3000+200+12×64+64×12 | 1.7 | 1.81 | 360-600 |

| SMF5-2 | 2 | 100+325×2300+100+12×64+64×12 | 1.7 | 2.35 | 300-590 |

| SMF5-5 | 5 | 100+200×1400+100+12×64+64×12 | 1.7 | 2.42 | 260-550 |

| SMF5-10 | 10 | 100+165×1400+100+12×64+64×12 | 1.7 | 3 | 220-500 |

| SMF5-15 | 15 | 100+165×1200+100+12×64+64×12 | 1.7 | 3.41 | 200-480 |

| SMF5-20 | 20 | 100+165×800+100+12×64+64×12 | 1.7 | 4.5 | 170-450 |

| SMF5-25 | 25 | 100+165×600+100+12×64+64×12 | 1.7 | 6.12 | 150-410 |

| SMF5-30 | 30 | 100+400+100+12×64+64×12 | 1.7 | 6.7 | 120-390 |

| SMF5-40 | 40 | 100+325+100+12×64+64×12 | 1.7 | 6.86 | 100-350 |

| SMF5-50 | 50 | 100+250+100+12×64+64×12 | 1.7 | 8.41 | 90-300 |

| SMF-75 | 75 | 100+200+100+12×64+64×12 | 1.7 | 8.7 | 80-250 |

| SMF5-100 | 100 | 100+150+100+12×64+64×12 | 1.7 | 9.1 | 70-190 |

| Note: Weight kg/m2, 5 layers sintered 8.4kg; 6 layers sintered 14.4kg 6 layers sintered mesh with another layer of 12 mesh to resist high pressure. Thichkess reaches 3.5mm |

|||||

| Data Sheet of 2-7 Layers Sintered Wire Cloth | |||||

| Item | Filter rating(um) | Structure (mesh /inch) | Thickness (mm) | Porosity (%) | Weight (kg/m2) |

| SMF2-T0.5 | 2-100 | Filter layer+60 | 0.5 | 60 | 1.6 |

| SMF3-T0.7 | 2-100 | 60 +Filter layer+60 | 0.7 | 56 | 2.4 |

| SMF3-T1.0 | 2-200 | 50 +Filter layer+20 | 1.0 | 58 | 3.3 |

| SMF3-T2.0 | 2-200 | Filter layer+20+8 | 2.0 | 58 | 6.5 |

| SMF4-T1.0 | 2-200 | 60+Filter layer+40+20 | 1.0 | 45 | 4.4 |

| SMF4-T1.7 | 2-200 | 40 +Filter layer +20 +16 | 1.7 | 55 | 6.2 |

| SMF5-T1.9 | 2-200 | 30 +Filter layer+ 60 +20 +16 | 1.9 | 52 | 5.3 |

| SMF5-T2.5 | 2-200 | 80 +Filter layer +30 +10 +8 | 2.5 | 55 | 8.8 |

| SMF7-T2.0 | 2-200 | 50 +filter layer+ 40 +20 +40 +filter layer+50 | 2.0 | 58 | 7.4 |

| Note: 1. Filter layer could be customized according to your demand. Other layer structures could be adjusted based on your specific requirement. |

|||||

| Technical Data Sheet of Sintered wire cloth and Perforeated Plate | |||||

| Model | Filter Rating (μm) | Structure | Thickness (mm) | Weight (kg/m²) | Porosity (%) |

| SMF-T2 | 2-200 | 30 +filter layer +30 +D4×P5×T1.0 | 2 | 6.7 | 57 |

| SMF-T2.5 | 2-200 | 30 +filter layer +30 +D5×P7×T1.5 | 2.5 | 9.8 | 50 |

| SMF5-T3 | 2-200 | 60 +filter layer +60 +20 +D6×P8×T2.0 | 3 | 11.9 | 50 |

| SMF5-T3.5 | 2-200 | 20 +filter layer +20 +10 +D8×P10×T2.0 | 3.5 | 12.6 | 54 |

| SMF5-T4.0 | 2-200 | 20 +filter layer +20 +10 +D8×P10×T2.5 | 4 | 14.2 | 55 |

| SMF5-T4.3 | 2-200 | 20 +filter layer +20 +10+D10×P13×T3.0 | 4.3 | 16.8 | 50 |

| SMF5-T5.3 | 2-200 | 20 +filter layer +20 +10+D10×P13×T3.0 | 5.3 | 20.6 | 51 |

| Note: Other structures could also be customized It’s suitable for higher differential pressure drop application. |

|||||

SMF-1: Multi-layer stainless steel sintered round discs in stainless steel

SMF-2: Arched square Titanium sintered mesh with laser cut install holes

SMF-3: Sintered mesh filter cartridge with fine mesh layer for air filtration

SMF-4: Laminated filter tube in 20um filter rate for oil & water filtration

SMF-5: High strength sintered mesh filter elements to resist coal industry high pressure drop

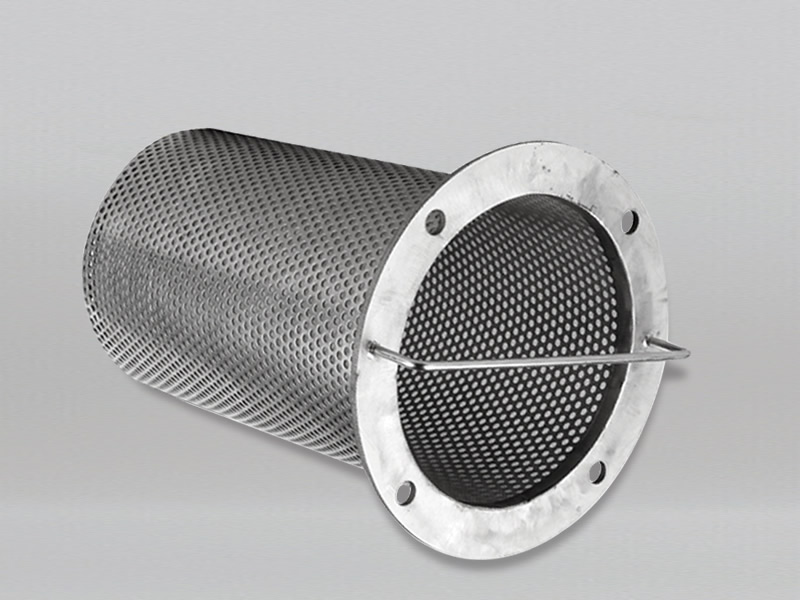

SMF-6: Sintered filter with perforated layer and spiral support rod outside to increase strength

SMF-7: Auto self cleaning sintered mesh filter elements for differential pressure environment

SMF-8: The sintered metal filter elements in three different sizes together used as gas turbine oil filter

SMF-9: Sintered mesh filter elements with long male threaded connector

SMF-10: Sintered mesh filter elements with short male threaded connector

SMF-11: Sintered mesh filter elements with hexagonal connectors

SMF-12: Sintered mesh filter elements with flange and handles

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Related Products

Products

Request A Quote

Complete our interactive form to receive a custom quote based on your needs.