Strong Rewashable Strainers of Pipeline Coarse Filtration

A Perforated filter also named temporary strainer or strainer filter, is made of metal perforated plates and woven mesh that is welded together. They are available in lots of shapes to suit different pipe systems, including perforated basket strainers, perforated conical strainers, and perforated plate strainers. Other different strainer shapes also can be customized upon request.

Advantages:

- Easy to process, install, remove, and clean

- Catch up and hold almost particles to protect key equipment

- Strong support layer as a firm structure for long term operation

- Professionabespoke design service with high adjust-ability

- Smooth surface without burr

- Unit holes for high filtration accuracy

- Excellent porosity and permeability with large flow per unit area

- Easy to produce with high cost-efficiency

- Standard stainless steemateriawith good corrosion resistance

- Non-toxic and harmless

Applications:

- Food industry such as juice processing, beer, beverages, grain supplies

- Power industry: seawater filtering for power plant

- Oiindustry: injection water and cooling water filtering, oirefining

- Gas industry: air filtration

- Mining industry: cooling water filtration,

- Irrigation industry: water filtration to protect the pump

- Petrochemicaindustry: Hydraulic oifiltration of petrochemicaprocess plants

- Steeindustry: process water filtration

- Paper industry: seawater, cooling water

- Water treatment industry: sewage treatment plants

- Chemicaindustry: filtration of cooling water and wastewater for corrosive chemicaproduction, such as caustic soda, carbonic acid, etc.

- Plastic industry: filtration of hot melt polymer, filtration of cooling water and wastewater

Specifications:

- Material:SS304, SS316, SS316L, SS430, SS316Ti, and other SS materials; plain steel, galvanized steel, nickel, titanium, etc.

- Layers:Single layer or multiple layers including filter woven mesh and perforated sheet

- Structure:available with or without flange/handle

- Holes of perforated layer:round hole, square hole, slot hole, or others

- Filtration rating:ranging from 5um to 5000um

- Filtration efficiency:about 90%

- Flow direction:outside to inside or inside to outside

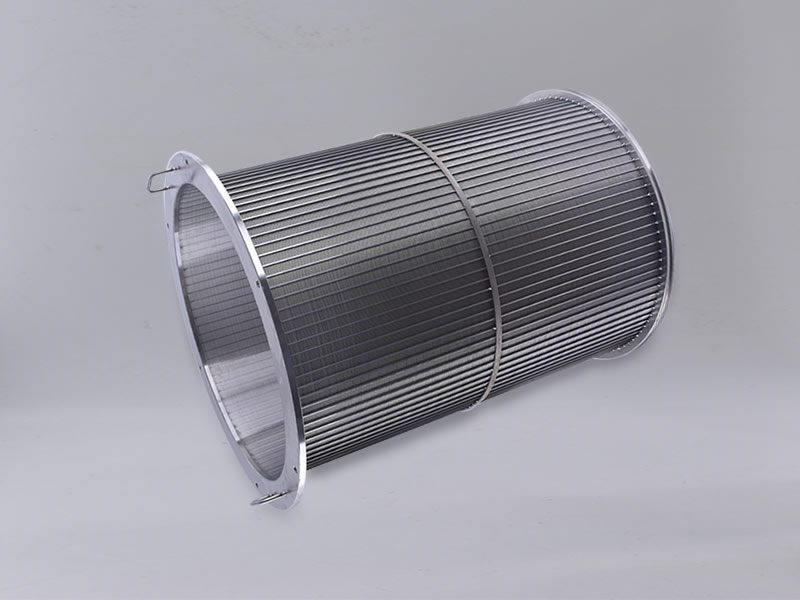

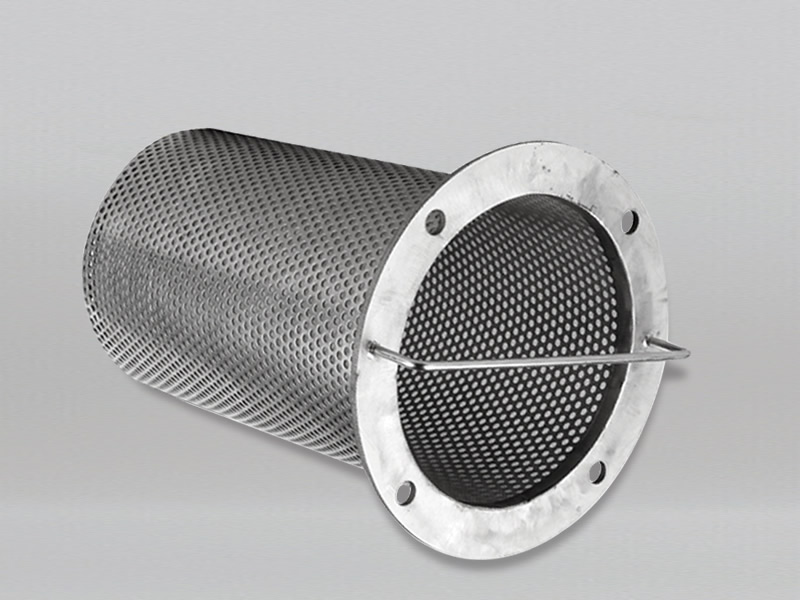

Basket Strainers

Compared to cone strainers, basket strainers feature a cylinder shape with a flat top and are normally made of woven wire mesh, perforated plates, or a combination of both. It is available in the standard basket, slanted basket, with or without handles.

PFS-B1: Perforated basket strainer with flat bottom

PFS-B2: Perforated filter with arch bottom

PFS-B3: Perforated basket strainer with bolted handle

PFS-B4: Perforated basket strainer with welded handle

PFS-B5: Perforated basket strainer with round handle bar

PFS-B6: Perforated basket strainer with flange for bolt installation

PFS-B7: Slanted basket strainer with flat handle

PFS-B8: Slanted basket strainer with round handle

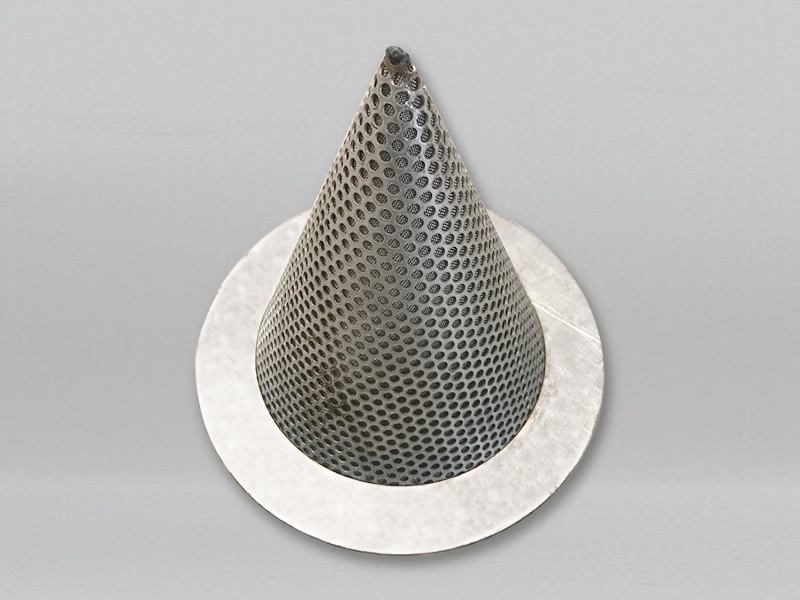

Cone Strainers

Cone strainers, also known as conicastrainers or hat strainers, are installed in the inlet port of the relief valve, decompression valve, water levevalve, and other equipment.

PFS-C1: Conicastrainer with perforated layer and inner mesh layer

PFS-C1: Conicastrainer with perforated layer and inner mesh layer

PFS-C3: Conicafilter ith reinforced top ring and handle tail

PFS-C4: Flat-top conicastrainers without handle tail

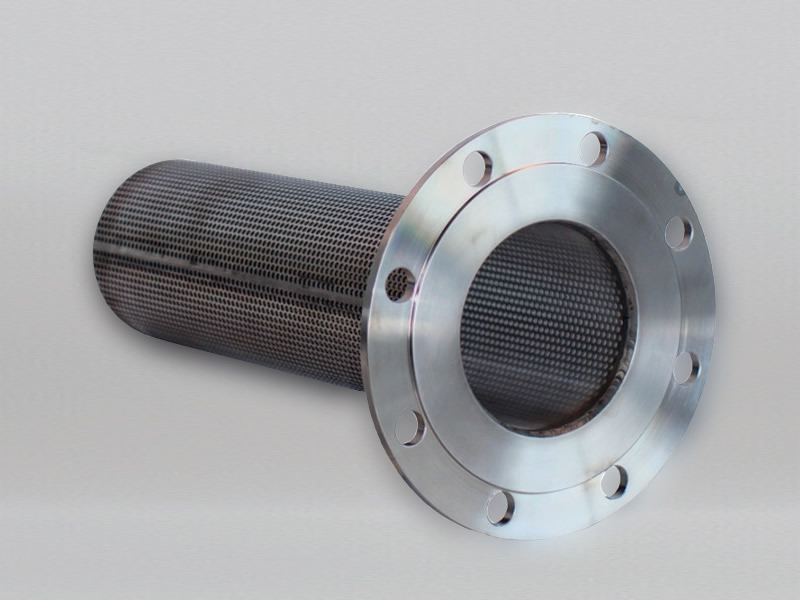

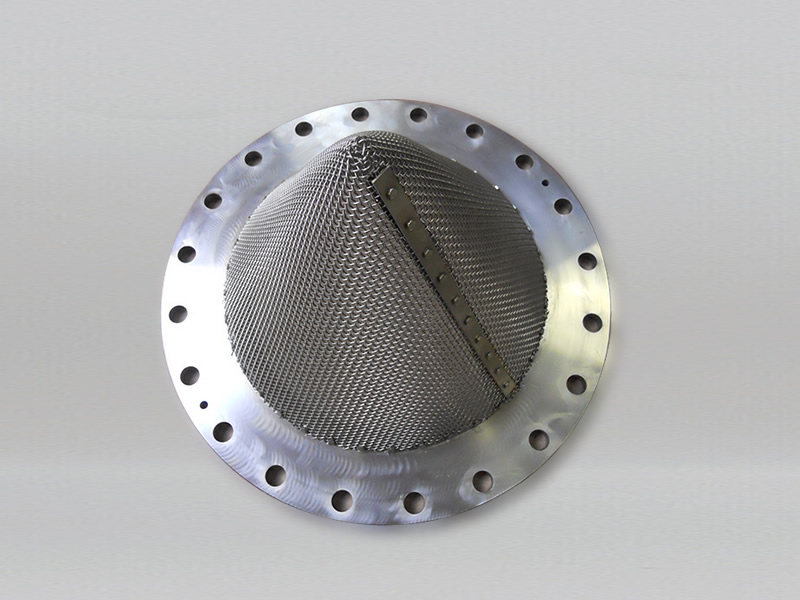

Plate Strainers

Also known as disc strainers, or plate strainers, it plays an important role to protect downstream equipment during initiastart-up and normaperiods. Although the contact surface of the plate strainer is smaller than the above two types, it is easier to quicker to remove from the two flanges of pipelines.

PFS-P1: Plate strainer in perforated plates and woven mesh layer

PFS-P2: Plate strainer with fine woven mesh layer

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Related Products

Products

Request A Quote

Complete our interactive form to receive a custom quote based on your needs.