Sintered Wire Mesh Plate Used for Agitated Nutsche Filter Dryer with Filtering Washing and Drying Function

Agitated nutsche filter/dryer ( ANF or ANFD ) is usually used for ultra-high purity industrial products, to separate the solid and liquid. When it works, it could fulfill the function of filtering, washing and drying in this equipment. The filter plate is usually made by sintered wire mesh plate. The sintered wire mesh plate can be welded with flange to be round filter plate or conical filter plate. It’s usually used in pharmaceutical, chemical, fine chemical and food industries to replace troditional fitler cloth. The sintered wire mesh plate has the feature of high strength, long lifetime, easy to change, etc.

We Filtalloy have rich experience on the production of sintered wire mesh plate. If you have any question, welcome to consult us! We’ll help supply the best filter solution!

Filtration: 1-300um

Temperature: -200~600℃

Structure: one whole piece or constructed by several parts.

Advantages:

- Robust for high-pressure vessel. The sintered wire mesh plate is constructed by several layers. These layers are sintered together. It has higher strength than non-sintered wire mesh.

- Uniform pore size and stable filtration. During operation with high pressure, the hole size is uniform. No wire mesh is destroyed during sintered process

- Easy to assemble. Each sintered wire mesh plate has installation hole. Customers can install it with nuts and bolts

- Easy to clean. It could be cleaned with water, chemical, ultrasonic, melt, baking and so on

- Long life-span: 20,000+ hours. For a different environment, it has a little difference. More details, pls consult our technical department.

| The Specification of High Flow Fluidizing Media | ||||

| Item | Air flow | Nominal thickness | ||

| CFM/ft² @ 2inches water | m³/m² @50.8mm water column | mm | inch | |

| FA-SFP-0005 | 5 | 1.524 | 1.37 | 0.054 |

| FA-SFP-0010 | 10 | 3.048 | 1.47 | 0.058 |

| FA-SFP-0025 | 25 | 7.62 | 1.57 | 0.062 |

| FA-SFP-0050 | 50 | 15.24 | 1.65 | 0.065 |

| Note: Other specifications could be customized and test. | ||||

| The Specification of Low Flow Fluidizing Media | ||||

| Item | Air flow | Nominal thickness | ||

| CFM/ft² @ 2inches water | m³/m² @50.8mm water column | mm | inch | |

| FA-SFP-0200 | 200 | 1.524 | 1.02 | 0.04 |

| FA-SFP-0400 | 400 | 3.048 | 1.19 | 0.047 |

| FA-SFP-0600 | 600 | 7.62 | 1.32 | 0.052 |

| FA-SFP-1000 | 1000 | 15.24 | 1.63 | 0.064 |

| Note: Other specifications could be customized and test. | ||||

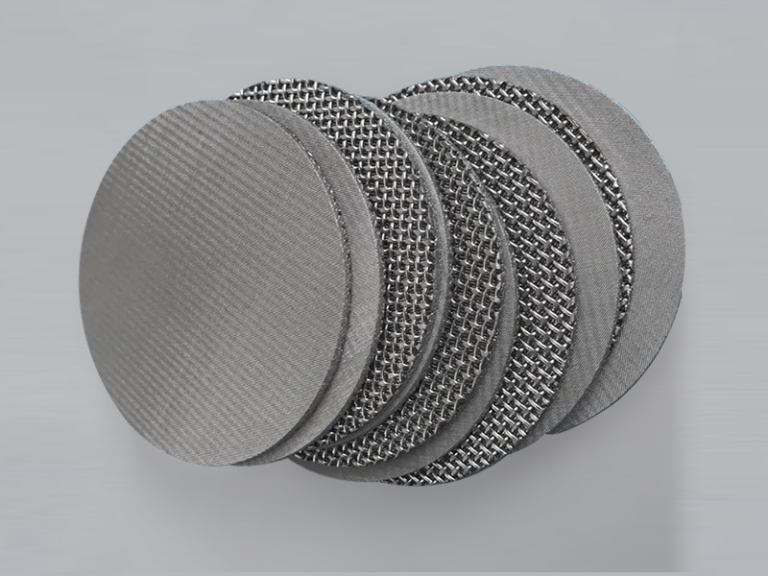

SFP-1: Sintered filter plate in single piece without outer frame

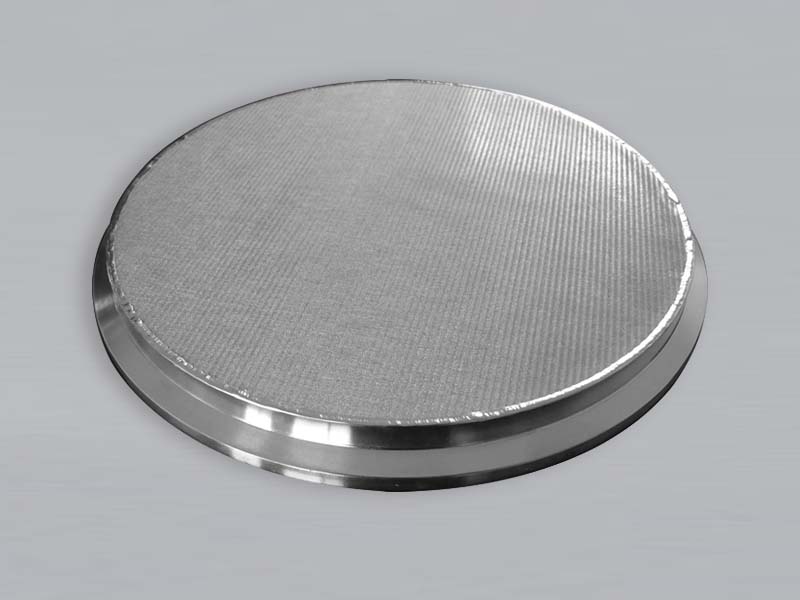

SFP-2: Sintered filter plate in single piece with metal frame for ANFD

SFP-3: Sintered filter plates for nutsche filter with flange and installation holes

SFP-4: Large sintered plate filter with 10 segments welded, without flange

SFP-5: Large sintered plate filter with 5 segments welded, with flange and installation holes

SFP-6: Large sintered plates with metal frame and center humps

SFP-7: ANF sintered filter plate with 14 separated segments for pigment & pharmaceutical industry

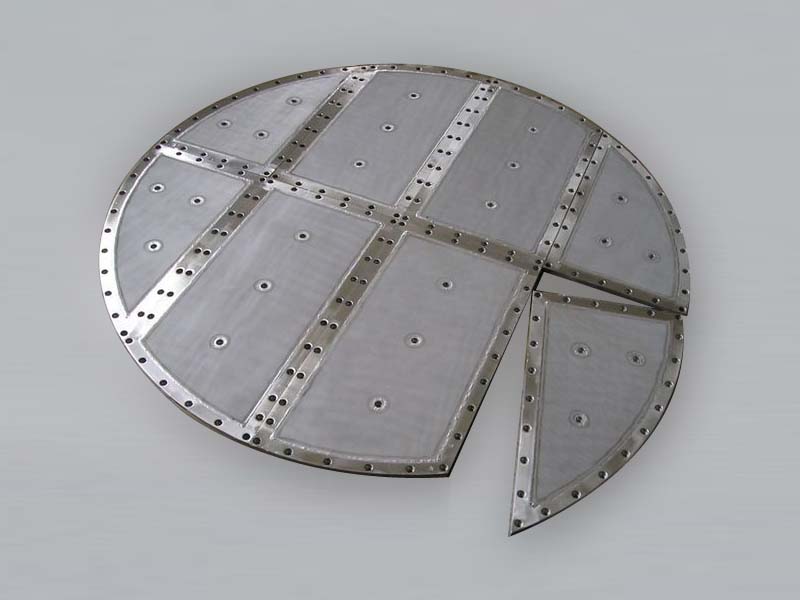

SFP-8: The sintered filter disc with 8 separated segments will be fixed through the installing hole

SFP-9: The ring shaped sintered filter disc can undertake high pressure drop

We Filtalloy manufacture the sintered wire mesh with good air permeability, which is good material for fluid bed dryer. The fluid bed dryer process the fine wet powder particles or particulate solids. When it works, the hot air will come in to dry these particles with certain pressure and make them fluidizing. Our sintered wire mesh will keep the particles in the vessel not escape.

SFP-10: Conical sintered wire mesh filter for fluid bed dryer

SFP-11: Cone fluidized bed filter with integrated pressed perforated layer

SFP-12: Cone fluidized bed filter with welded perforated layer

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Related Products

Products

Request A Quote

Complete our interactive form to receive a custom quote based on your needs.