First, we need to understand that stainless steel sintered felt is made of metal fibers. The diameter can reach micron. So, how are micron-level metal fibers produced?

Contents

What is Wire Preparation?

I. Bundled Drawing Method

1. Material Preparation

2. Material Bundling

3. Multiple Cold Drawings

4. Annealing

5. Finishing

II. Cutting Method

III. Melt Manufacturing

1. Melting

2. High-Speed Wire Spinning

IV. Comparison of the Three Methods

Summary

Questions

1. What materials can be used to make fibers?

2. What properties do the materials need to possess?

3. What quality control standards are required during metal fiber production?

In our industry, the production of metal fibers is called “wire preparation.”

Wire preparation combines metallurgy, materials processing, and precision machinery. Materials primarily include SS316L, copper, titanium, and nickel.

There are three main metal fiber forming technologies, including bundle drawing, cutting, and melt spinning.

I. Bundle Drawing Method

Bundle drawing method is the core technology of high-end continuous fibers.

1. Material Preparation

First, the metal is formed into 0.5mm filaments and annealed to reduce hardness, increase plasticity, and prevent breakage during drawing. The surface is then pickled to remove the oxide layer.

2. Material Bundling

Hundreds to thousands of filaments are arranged in parallel and seamlessly encased in a dissolvable metal sleeve, typically made of pure iron or copper. A special drawing oil is applied to the surface to reduce friction.

3. Multiple Cold Drawings

Cold drawing is performed using a special alloy die. Each draw must reduce the diameter by ≤20% to prevent breakage. Repeated drawing cycles are performed using dies with gradually decreasing diameters.

Producing micron-sized fibers requires hundreds of these steps. For example, 50-100 draws are required to produce fibers from 0.5mm to 1μm, resulting in an elongation of 250,000 times.

4. Annealing

After every 3-5 cycles, the metal’s hardness increases and its plasticity decreases. Annealing is then required to restore plasticity and prevent fiber breakage.

5. Finishing

The composite bundle is pickled to remove the coating, resulting in a qualified product, micron-sized fibers.

II. Cutting Method

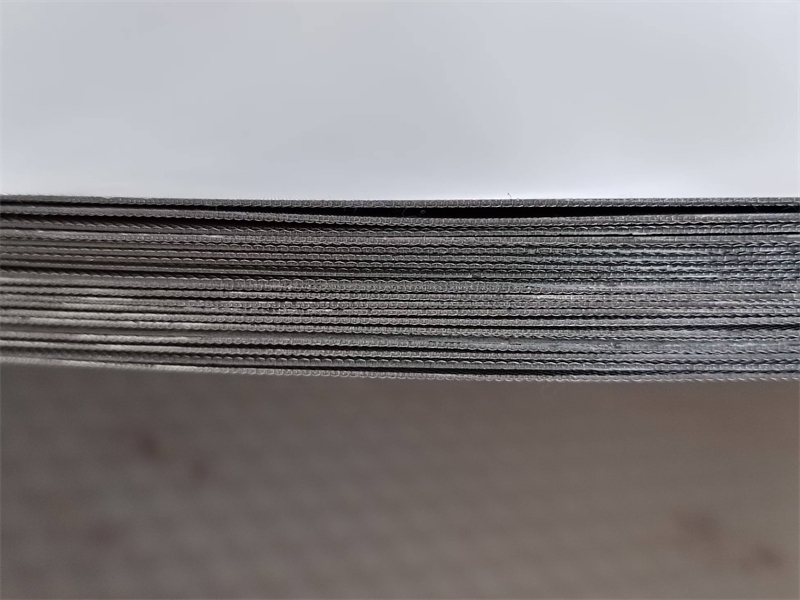

Using alloy cutting tools to cut metal sheets, the finished fibers are obtained.

This method requires high-precision CNC machining to control cutting speed and feed rate, as well as tool parameters, to ensure fiber continuity and integrity. Cutting fluid is used for cooling and lubrication to prevent thermal deformation.

III. Melt Production

Main Methods for Economical Fiber Production

1. Melting

Heating the metal material to a molten state requires precise temperature control to ensure fluidity.

2. High-Speed Spinning

The molten metal passes through a centrifuge at a speed of 10,000-30,000 rpm. The liquid flows through the spinneret holes, rapidly cooling and solidifying to form fibers, typically in a disordered, cotton-like state. Fiber diameter is affected by hole size and pressure.

IV. Comparison of Three Methods

These three methods differ in their principles, economics, and manufacturing speed. Pls check the following comparison.

| Production Method | Fiber Morphology | Diameter(μm) | Production Cost | Fiber Strength(GPa) | Application |

|---|---|---|---|---|---|

| Bundle Drawing Method | Continuous filament | 1-50 | Very high | 1.5-2.5 | High-end precision filtration, textile materials |

| Cutting Method | Short yarn | 20-200 | Middle | 1.0-1.8 | Metal sintered filters, filter materials |

| Melt Spinning Method | Short yarn | 10-100 | Low | 0.8-1.2 | Insulation materials, conductive materials |

Summary

Bundle drawing, cutting, and melt spinning are all mature techniques that require highly experienced engineers. Experience plays a crucial role.

Question:

1. What materials can be used to make fibers?

Many materials can be used to make fibers, including SS316L, copper, titanium and nickel. SS316L sintered felt is used for dust collection. Titanium sintered felt and nickel sintered felt is used in electrolyzed water industry.

2.What properties do the materials need to possess?

The above materials need to have good ductility to meet the characteristics of the processing method

3.What quality control standards are required during metal fiber production?

Fiber quality must be tested against multiple indicators. We list some for reference.

- Appearance Inspection

The fiber’s color is uniform, free of color difference, stains, regular shape, and no breaks.

- Diameter Parameters

Diameter and length are strictly controlled to ensure product consistency. The fiber products are tested using high-precision equipment (such as electronic strength meters, laser particle size analyzers, and online melt index testing) to control the fiber’s mechanical properties and dimensional parameters to ensure accuracy.