Stainless Steel Introduction

Stainless steel is a versatile and popular material used in a variety of industries due to its numerous beneficial properties. This article will introduce stainless steel with its chemical composition, performance characteristic, series classifications, and applications.

Catalog

1. Chemical Composition

Stainless steel is composed of iron, carbon, and at least 10.5% chromium. The chromium element is the main component of stainless steel, which acts as a protective layer against oxidation and corrosion. Other common elements found in stainless steel include nickel, molybdenum, and nitrogen. These elements play varying roles in enhancing stainless steel’s properties such as strength, ductility, and corrosion resistance.

2. Performance characteristics

- Corrosion resistance: Stainless steel has corrosion resistance and can be used for a long time in an environment where humid or harmful elements exist. Especially in the acid-base environment, stainless steel shows good corrosion resistance.

- High-temperature intensity: Stainless steel can still maintain high strength and toughness at high temperatures, and can be used for a long time at high temperatures. This feature makes it widely used in the field of high temperature and high pressure in the working environment.

- Abrasion resistance: After special treatment, the surface of stainless steel can improve its hardness and abrasion resistance and increase its service life. Especially under mechanical effects such as stirring, the working life of stainless steel equipment can be greatly extended.

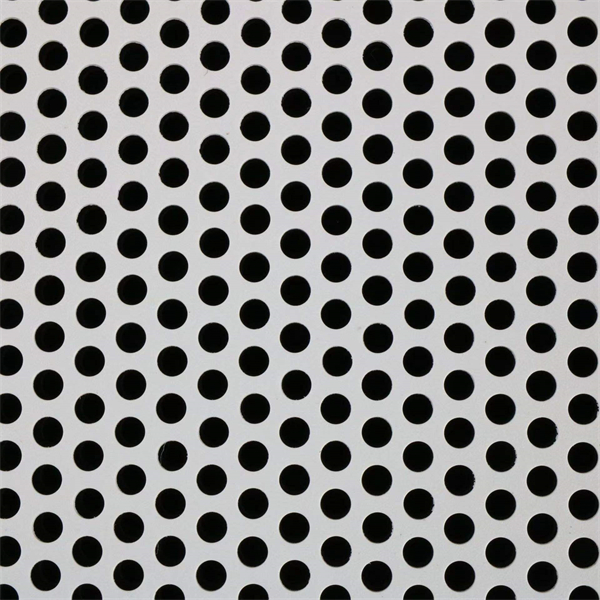

- Ductility: Stainless steel has good ductility and can be processed into various shapes, sizes and surface treatments. At the same time, punching, expanding, drawing and other molding processing can be performed, so that it can meet the needs of various complex industrial manufacturing processes.

3. Series Classifications

Stainless steel is classified into five different series based on their microstructure and properties. These series are:

- Austenitic: The most commonly used series features excellent weldability, good formability, and high resistance to corrosion. Examples of austenitic stainless steel include 304 and 316.

- Ferritic: Features lower chromium content and higher iron content, making it more affordable and magnetic. It is commonly used in appliances, cookware, and automotive applications. Examples include 430 and 434.

- Martensitic: Known for its hard and brittle characteristics, has high carbon content, mainly used for cutlery and tools.

- Duplex: Features a two-phase microstructure of austenitic and ferritic stainless steel, offering good strength and corrosion resistance. Examples include 2205 and 2304.

- Precipitation-hardening: Special types of austenitic and martensitic grades, optimized for high strength and hardness. Examples include 17-4PH and 15-5PH.

4. Applications

Stainless steel has a wide range of applications in various industries, including:

- Construction industry: used in building facades, bridges, handrails, and structural support.

- Automotive: used in exhaust pipes, engine parts, and window trims.

- Aerospace and defense industry: used in aircraft and missile components.

- Medical industry: used in surgical equipment, implants, and prosthetics.

- Food industry: used in kitchen utensils, cookware, and food processing equipment.

Conclusion

Stainless steel has become an important material due to its remarkable properties and diverse range of applications. The chemical composition, production methods, series classifications, and applications of stainless steel provide insight into why it has become so widespread in industry.