Content

1. What is Mild Steel?

2. What are the Benefits of Using Mild Steel?

3. The Disadvantages of Using Mild Steel?

4. What is Stainless Steel 304?

5. What are the Benefits of Using Stainless Steel 304?

6. The Disadvantages of USing Stainless Steel 304

7. Mild Steel and Stainless Steel 304: Which Material is the Suitable Material for Extruder Screen?

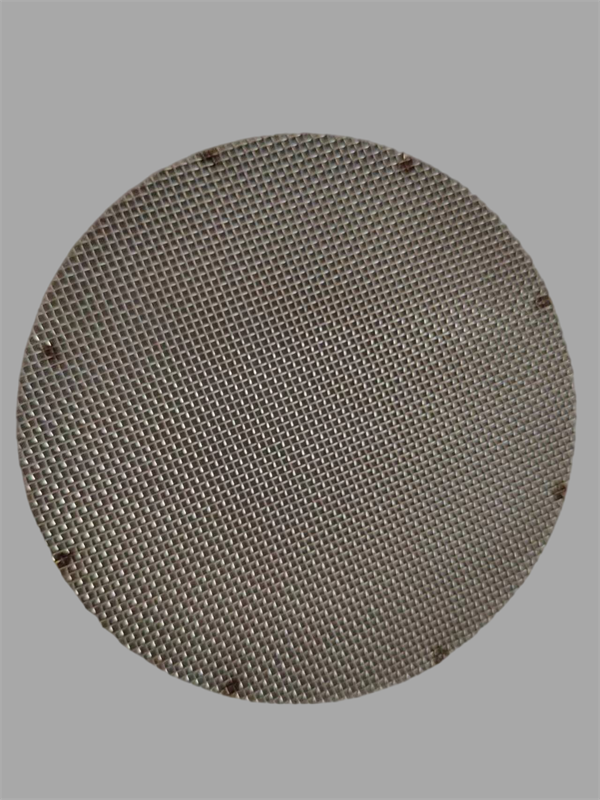

The extruder screen is a product that is generally used in plastic extrusion machines. The extruder screen is punched by the weaving metal wire cloth through the die mold. Common materials are mild steel and stainless steel. The cost of these two materials is different. Because the extruder screen is consumable product, reducing costs is the key factor. Let’s introduce the two materials below:

1.What is Mild Steel?

The chemical components of mild steel mainly include Carbon, Silicon, Manganese, Phosphorus, and Sulfur. The following is the content:

C 0.05-0.25%, Mn 0.25-0.8%, Si 0.15-0.35%, S<=0.05, P<=0.04%

Increased carbon content can improve the hardness and strength of steel. We all know that the hardness of mild steel is greater than the hardness of stainless steel

2.What are the Benefits of Using Mild Steel?

l High Strength

Mild steel has high hardness and strength. When the extruder is working, the extruder screen should bear high pressure. The single-layer of mild steel extruder screen can withstand the pressure, which also reduces production costs.

l Can Be Reused

Due to the low carbon content, mild steel is a soft steel, which can be described. When the mesh is blocked, it needs to be heated to remove the impurities, and the extruder screen can be reused several times.

l Low Cost

The cost of mild steel is low. For the same mesh and specification, the cost of stainless steel is several times that of mild steel.

3.The Disadvantages of Using Mild Steel?

l Mild Steel Can Only Work Below Temperature 150℃

Mild steel is generally used for structures with a working temperature below 150℃. Exceeding this temperature, the mild steel will be oxidized. The extrusion process is usually used for plastic processing. During this process the plastic particles will be melt into polymer under high temperature. Mild steel mesh is limited to the working temperature. So it only suitable some of plastics, such as PP, HDPE.

l The Anti Corrosion Ability of Mild Steel is Worse Than Stainless Steel 304

The anti corrosion ability of mild steel is worse because it has less Nickel. When making particles with the recycled plastics, the material mixed with other impurities. If it mixed with strong corrosion material, the mild steel of extruder screen can’t be used.

4.What is Stainless Steel 304?

Stainless steel 304 material is a common material in stainless steel. Various chemical composition is as follows:

C <= 0.04%, Mn <= 2.00%, P <= 0.045%, S <= 0.03%, Si <= 1.00, CR 18-20%, Ni 8-11%

Due to the corrosion resistance of Cr and Ni, stainless steel 304 has good ability to resist corrosion.

5.What are the Benefits of Using Stainless Steel 304?

l Low Cost than Other Stainless Steel

Stainless steel 304 is a common stainless steel, and the cost is low than other stainless steel.

l Work at High Temperature

Stainless steel 304 high temperature resistance, generally working temperature below 450℃. The general temperature heated by stainless steel extruded mesh is below 400℃, and most of the plastic can be use it

l Resist Corrosion

Stainless steel 304 has good corrosion resistance. Generally waste plastic recycled is used for extrusion process, and this material is selected.

l Good Ductility

Stainless steel 304 has good ductility, which can be processed into extruder screens or extruder cylindrical filters.

6.The Disadvantages of Using Stainless Steel 304

l Cost is Higher Than Mild Steel

Stainless steel 304 cost is higher than mild steel.

l Strength lower than Stainless Steel 304

The strength of stainless steel 304 is lower than mild steel. Because stainless steel 304 has lower carbon content. If the extruder screen working pressure is large, it needs to use the multi-layer electro welded discs to increase the pressure proof ability.

7.Mild Steel and Stainless Steel 304: Which Material is the Suitable Material for Extruder Screen?

Please comprehensively refer to the working temperature, corrosion, and strength of the extruder screen, and then select the material. We Filtalloy have more than 20 years of production experience. We can help you choose the suitable solutions to ensure that the extruder screen to meet your demand.