When the quality requirements of the product are high or needed high, such as production cable insulation materials, cable core wires, transparent products, thin film, medical products, single silk, etc. Generally choosing 20 – 250 mesh extruder screen, the number of layers is 1-5 layers. If it is multi -layer spot welded packs, the fine filter layer is usually placed in the middle, and the thick mesh in both sides. The coarse mesh that is close to the diversion plays a supporting role to prevent the fine mesh from being squeezed by the high-pressure melt, which is called the support layer. During the extrusion process, the impurities in materials, transportation and ingredients in raw materials, the burnt material of the melt, and the unpolished materials are blocked by the extruder screen. And all these accumulate on the surface of the extruder screen. As a result, the aperture of the extruder screen is blocked. Driven by the screw, the pressure of the melt in the screw groove is rapidly increased. When the pressure exceeds the tolerance of the extruder screen, it is broken. It will cause the product unqualified.

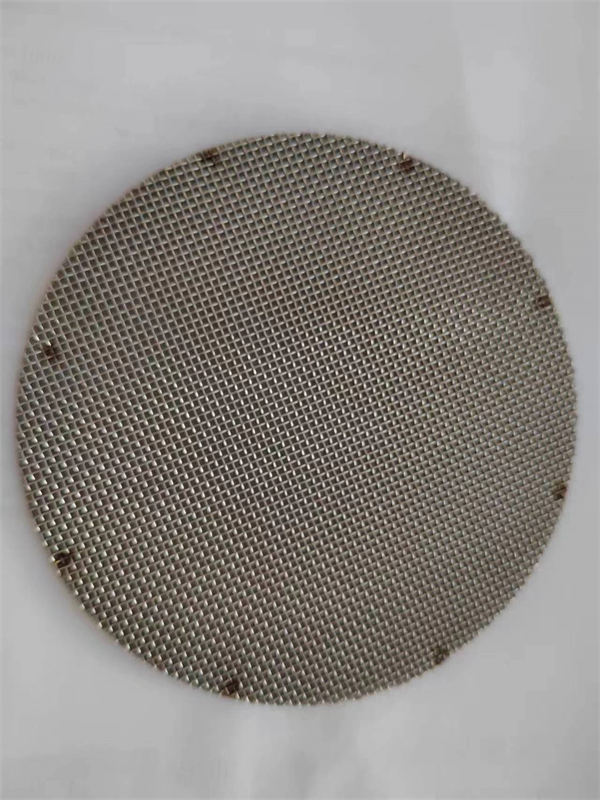

The wire cloth used for plastic extruded is stainless steel wire mesh, copper wire, black steel wire mesh, or other metal wire mesh. Different metal wire cloths are woven according to a certain of specifications. Stainless steel wire cloth is the most popular. The wire cloths are punched into different dimensions of extruder screens. Traditional extruder screen, including coarse layer, filter layer and support layer. The coarse layer is generally 40-100 mesh, with 80-250 mesh of fine layer, and the support layer is more than 20 mesh.

If the mesh number of support layer is large, the wire diameter of the mesh is small, and the pressure to bear is limited. The filter layer of extruder screen is easily squeezed; if the mesh of support layer is small, the pore diameter of the mesh is large rupture. At the same time, the percentage of the size of the pore size and the size of the pore area used in the extrusion molding also has a lot to do with whether the filter is easy to rupture. Therefore, it is difficult for ordinary support mesh. The requirements of the process need to seek a new type of filter that is safe, durable, and not easily damaged. According to the characteristics of the squeezing molding process, a new type of dutch weave mesh is designed.

The structure of the dutch weave mesh is dense, and the diameter of the mesh is moderate. The mesh has a certain hardness and flexibility. Ensure that it is stable and reliable under high -pressure extrusion conditions to ensure that the filter does not break.