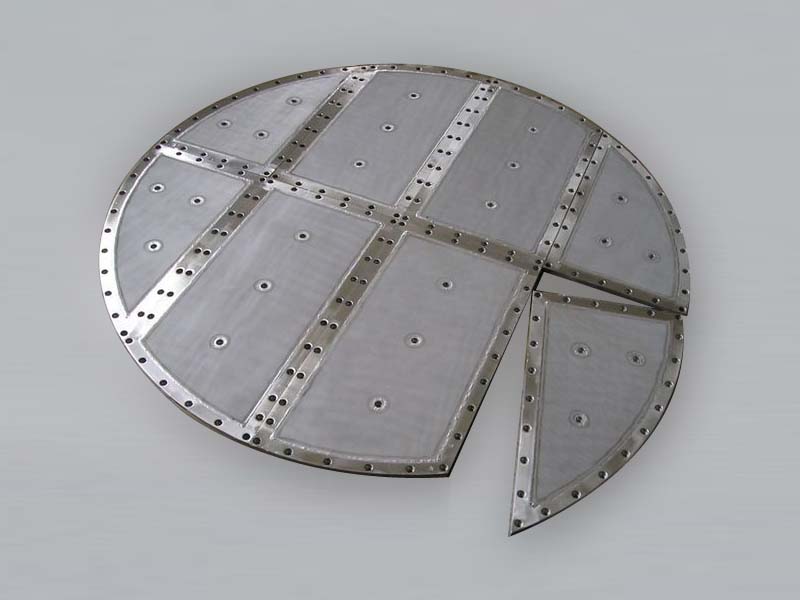

Asymmetric Sintered Metal Filter for Gas and Liquid Filtration

Filtalloy developed and researched the asymmetric sintered metal filter technique. It could reach 0.1um filtration and meet more industries higher demand on precise product. The fine filter film and coarse film is combined together to improve the filter performance on filtration precision and permeability. The thickness of film is 200um. The filter media could pass through rapidly and big particles are held up from surface.

The asymmetric sintered metal filter with fine film could filter very fine particles and permit high flow passing.

| Technical Data Sheet of Asymmetric Sintered Metal Filter | ||||||

| Code | Filter rating(μm) | Porosity(%) | Bubble Point Pressure (Pa) | Outer dia.(mm) | Length(mm) | Material |

| ASM-F0.5 | 0.5 | 25 | 11960 | Max 400mm | Max 1600mm | SS304L and 316L, Nickel, Titanium, Monel, Inconel, Hastelloy and other |

| ASM-F1.0 | 1 | 30 | 8280 | |||

| ASM-F2.0 | 2 | 40 | 5230 | |||

| ASM-F5.0 | 5 | 40 | 4100 | |||

Advantages:

- Filtration accuracy and stable. Our asymmetric sintered meter filter membrane improve the retention rate to 99%, which is far more than usual material 95%.

- High permeability because of the asymmetric structure

- Surface filtration, easy to backwash

- Double membrane structure. Filtration layer could be protected and extend the filter lifespan.

Applications

- Filtering and recycling of diverse catalysts in Petroleum refineries and Petrochemical plants

- Gas and liquid filtration field, which has lower micron demand

- Renew energy, battery material filtration

- Other precise filtration industry

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Related Products

Products

Request A Quote

Complete our interactive form to receive a custom quote based on your needs.