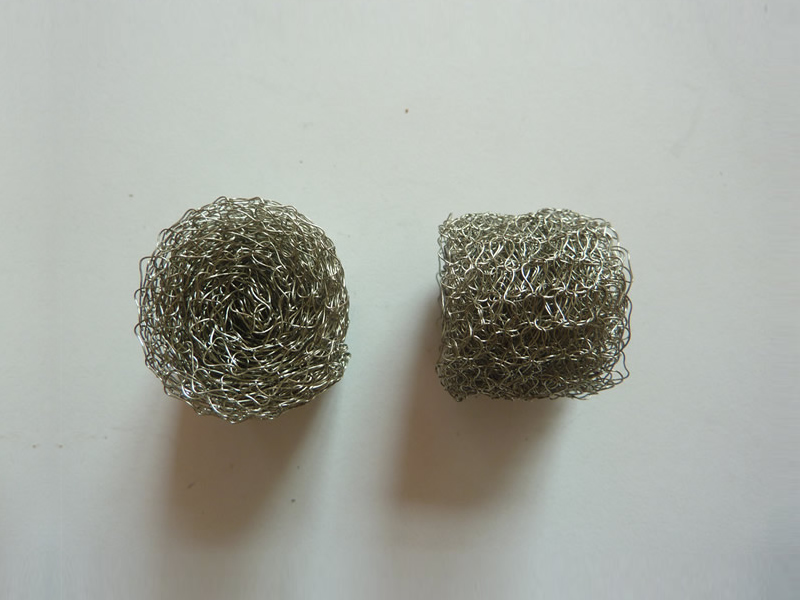

Stainless Steel Wire Mesh Pleated Cartridge

Increasing Filtration Area and Improve Filter Efficiency

The pleated metal filter element are constructed with supporting layers and filter layer, pleated then welded together. With a supporting layer, it could undertake the high pressure. With the pleated process, it increases the filtration area several times more than the usual candle filter. Because of this, pleated metal filter element shortens the filter time and improves the filter effectiveness.

It’s an ideal material for polymer metal filter element on fibers, films and resins. It’s also widely used for chemical fiber, textiles and plastic industries. We design a range of products to meet the diverse filtration, separation, and purification demand

Advantages:

- High flow rates. The pleated process increases the filter area and dirt holding capacity. The pleated metal filter element reduces the differential pressure and saves the filter cost.

- Long on-stream life time. The pleated metal filter element has supporting layer to protect the filter layer avoiding being destroyed. Besides, when customer install in their equipment, there’s perforated tube inside or outside to protect the pleated metal filter element. These help extends the lifespan, reduce downtime and save cost.

- Easy to clean. TPleated filter element can be washed by superheated steam, chemical, Ultrasonic and other methods to remove the contamination. We have a skilled technical department to solve the critical cleaning problems to extend the filter on-stream lifetime. If you have any quesitons, pls contact us.

Applications:

- Polymer filtration- PE, LDPE, PET, PP, PA, PBT, PC, PEEK, BOPET, BOPP, PMMA, EVA,

carbon-fiber , fiber, resin, film, sheet, etc. - Liquid/solid filtration food and beverages, pharmaceutics, chemicals, hydraulic, lube and fuel

filters, inkjet printers, petrochemical processes and more. - Gas/solid filtration

- Oil refinery, chemical processing ( ammonia gases, polysilicon, EDC, olefins gases, …), or

smelting (Ni, Pt, Cu, Al …), coal gasification, cement and steel production, nuclear filtration and

many more.

| The comparison of polymer filter element with different filter layer | ||

| Item | Woven mesh for filter layer | Filter fiber as filter layer |

| Filter media | Hard particulate | Hard particle and deformable gel |

| Filter micron | 5-400 micron | 1-100 micron |

| Dirt holding capacity | Low | High |

| Permeability | Good | Good |

| Work differential pressure | High | High |

| Work temperature | High | High |

| Repeat cleaning | Yes | Yes |

| Corrosion resistant | Good | Good |

PMF-1 Stainless steel folding oil filter element

PMF-2 Stainless steel filter cartridges with reinforced plate

PMF-3 Metal pleated filter cartridge with supporting layer inside suitable for filtration from outside to inside

PMF-4 Stainless steel filter cartridges with supporting layer, suitable for polymer melt filtration from inside to outside

PMF-5 Stainless steel filter cylinder with reinforced belt for air filtration

PMF-6 Stainless steel candle filter without reinforced belt

PMF-7 Hydraulic oil filter element with female threads

PMF-8 Pleated stainless steel filter cartridge with male threads for oil filter

PMF-9 Stainless steel pleated filter with flange for liquid filtration

PMF-10 Stainless steel cartridges filter with handles for pharmaceutic industry

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Related Products

Products

Request A Quote

Complete our interactive form to receive a custom quote based on your needs.