Hot Gas Filtration Elements With Good Ability on

Resist Thermal Shock and Mechanical Robustness

Filtalloy manufactures the sintered metal filters for hot gas dust filtration, which are normally named as hot gas filtration elements, or sintered metal fiber filter bags. It’s constructed by coarse woven mesh, coarse fiber, and fine fiber, sintered in a vacuum furnace at high temperatures. The pore size is uniform and stable. Compared with non-woven fabric, it’s self-supporting, with no need to add a filter cartridge. Even the filter material made of PTFE could only resist temperature 260℃. Our sintered metal filter could work up to 1000℃. Although ceramic material could work well in a high-temperature environment, when the filter exceeds a certain length, it has the risk of breakage at the beginning of the system’s starting work. There’s vibration because of the pressure pulse. The sintered metal filter is the optimized choice.

Advantages:

- Easy to install, panel holes don’t need to change

- High strength to resist high-pressure drop

- Excellent material to resist high temperature

- Resist corrosion

- Filtration efficiency> 99.99%.

- Emission level reaches government requirement, 5mg/m3

- Filtration: less than 1um

- Resist to heat shock

- Fire-proof

- Cleanable, online clean and offline clean

- Longer lifespan

Application Industries:

✔️ Alumina Oxide

✔️ Glass industry

✔️ Power generation

✔️ Metallurgical industry

✔️ Desulfurization denitration process

✔️ Waste incineration furnace

✔️ Catalyst recovery

The sintered metal fiber felt filter could be made by fibers only or combined together with wove mesh to increase the robust strength.

Metal fiber hot gas filter elements could reach emission removal less than 5mg/m3.

Hot gas filter element easy to install. The previous dust collector panel hole don’t need to change.

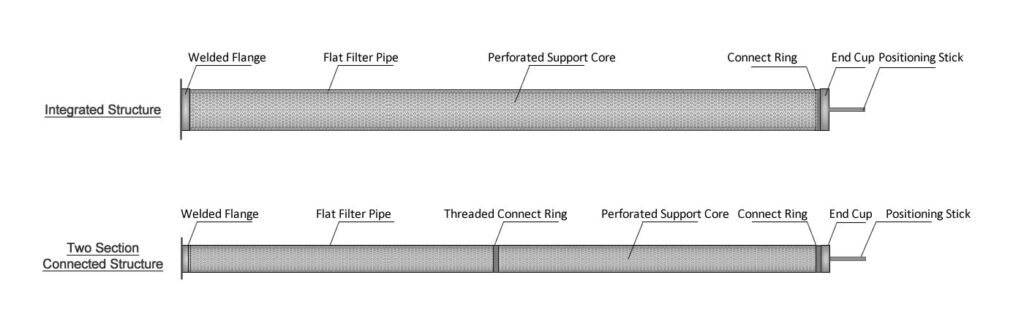

Filtalloy supplies two structure choices: integrated structure and two-section connected structure. Pls refer to the drawing below to compare:

Standard materials are available in SS316L, SS310S, 0Cr21Al6, here we list a simple comparison of these materials, and hope it is helpful to choose suitable material. Meanwhile, special alloy materials are also can be customized according to clients’ requirements.

| Parameter of Hot Gas Filtration Elements | ||||

| Material Capacity | Unit | SS316L | 310S | 0Cr21A6 |

| Material Density | g/cm3 @20℃ | 7.98 | 7.98 | 7.16 |

| Melt point temperature | ℃ | 1400-1450 | 1400-1450 | 1500 |

| Oxidation temperature | ℃ | 400 | 600 | 800 |

| Restoration temperature | ℃ | 550 | 800 | 1000 |

| Thickness | mm | 0.65 | 0.65 | 0.65 |

| Porosity | % | 75 | 75 | 68 |

| Air permeability | m3/m2/min @0.2Kpa | 21-27 | 21-27 | 21-27 |

| Filtration efficiency | % | >99.99 | >99.99 | >99.99 |

| Emission | Mg/m3 | <5 | <5 | <5 |

| Tensile strength | N/mm2 | ≥20 | ≥20 | ≥20 |

| Test standard: BS 2782 Application environment: Al2O3 dust, wind speed 1.75-3m/min, dust density 10g/m3 |

||||

Specifications:

| Specification of Hot Gas Filtration Elements | ||||

| Product ID | OD (mm) | ID (mm) | Length (mm) | Filtration area (m2) |

| FLA-130/1500 | 130 | 128 | 1500 | 0.61 |

| FLA-160/1500 | 160 | 158 | 1500 | 0.75 |

| FLA-130/3000 | 130 | 128 | 3000 | 1.22 |

| FLA-160/3000 | 160 | 158 | 3000 | 1.5 |

| FLA-130/4000 | 130 | 128 | 4000 | 1.63 |

| FLA-160/4000 | 160 | 158 | 4000 | 2.01 |

| FLA-130/5000 | 130 | 128 | 5000 | 2.04 |

| FLA-160/5000 | 160 | 158 | 5000 | 2.51 |

| FLA-130/6000 | 130 | 128 | 6000 | 2.45 |

| FLA-160/6000 | 160 | 158 | 6000 | 3.01 |

| FLA-60/1500 | 60 | 56 | 1500 | 0.28 |

| FLA-60/2000 | 60 | 56 | 2000 | 0.38 |

| FLA-60/3000 | 60 | 56 | 3000 | 0.57 |

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Related Products

Products

Request A Quote

Complete our interactive form to receive a custom quote based on your needs.