Sintered Metal Fiber Felt with Porous Construction for Gas Filter

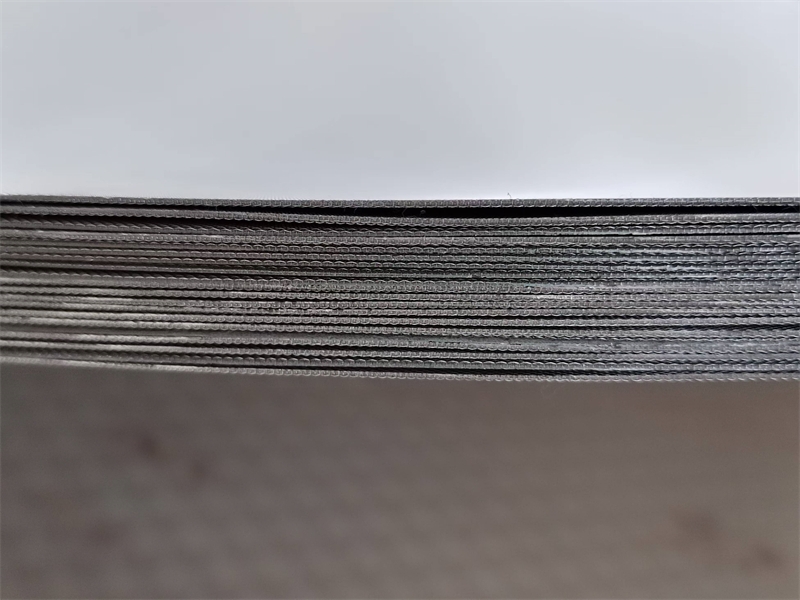

Sintered metal fiber felt is produced in a vacuum furnace, with metal fibers randomly laid. We select the fiber diameters and basis weight precisely, then control the pore diameter through thickness. The sintered metal fiber felt keeps a three-dimensional reticulated porous structure with high permeability, low-pressure drop, and excellent dirt holding capacity. The bigger particle could be captured at the outside surface, and small particles pass through the sintered metal fiber felt.

The metal fiber felt is usually sintered together with metal wire mesh to enhance the strength and subsequent longer on-stream life. Sintered metal fiber felt could be cleaned in sit and minimized the shutdown time, saving cost.

The usual available material is stainless steel 316L, 310S, Titanium, Nickel, Hastelloy, Inconel, FeCrAl, etc. The sintered metal fiber felt is mainly used for gas filter, hydrogen production by water electrolysis and polymer filter. We have rich experience and could help suggest the most siutable material. If you have questions on choosing sitnered metal fiber felt, pls contact us.

Advantages:

- Resist high temperature and corrosion

- Suitable for critical air and liquid filtration application

- High air permeability, low-pressure drop

- High contaminants holding capacity, pleated structure available

- Cleanable in situ, minimize maintenance and shutdown time

Features of Stainless Steel Sintered Fiber Felt:

| Stainless steel sintered fiber felt | |

| Materials | Stainless steel fiber |

| Filter rating | 2-100um |

| Length | 48” |

| Width | 48” |

| Thickness | 0.3-1.2mm |

| Porosity | 75%-85% |

Applications:

- Liquid and gaseous ammonia

- Steam filtration

- Electronic high-temperature gas dust removing

- Polymer filtration and polyester melt purifying

- Hydraulic filtering

- Catalyst retention and recovery

- Gasification

- Pharmaceutical powder recovery

- Ultra filtration pre-filter, refining process

- PEM electrolyzer, AEM electrolyzer, ALK electrolyzer

Structure & Specifications:

The sintered metal fiber felt filter could be made by fibers only or combined together with wove mesh to increase the robust strength.

Titanium sintered fiber felt without mesh

SS316L sintered fiber felt with mesh

Pleated sintered fiber felt

| Specification of Metallic Fiber Felt | |||||||

| Code | Efficiency (μm) | Thickness (mm) | Thickness (inch) | Porosity (%) | Bubble Point (Pa) | Bubble point (psi) | Permeability (L/dm².min) |

| SFF-F3 | 3 | 0.37 | 0.0146 | 67 | 13000 | 1.89 | 13 |

| SFF-F5 | 5 | 0.30 | 0.0118 | 75 | 6800 | 0.99 | 47 |

| SFF-F7 | 7 | 0.36 | 0.0142 | 74 | 5050 | 0.73 | 60 |

| SFF-F10 | 10 | 0.34 | 0.0134 | 78 | 3700 | 0.54 | 85 |

| SFF-F15 | 15 | 0.38 | 0.0150 | 80 | 2470 | 0.36 | 170 |

| SFF-F20 | 20 | 0.51 | 0.0201 | 82 | 1850 | 0.27 | 265 |

| SFF-F25 | 25 | 0.62 | 0.0244 | 79 | 1480 | 0.21 | 325 |

| SFF-F30 | 30 | 0.62 | 0.0244 | 79 | 1235 | 0.18 | 450 |

| SFF-F40 | 40 | 0.63 | 0.0248 | 76 | 900 | 0.13 | 620 |

| SFF-F60 | 60 | 0.57 | 0.0224 | 83 | 600 | 0.09 | 1350 |

| SFF-F86 | 86 | 1.00 | 0.0394 | 84 | 480 | 0.07 | 1470 |

| SFF-F80 | 80 | 1.00 | 0.0394 | 85 | 450 | 0.07 | 1510 |

| SFF-F90 | 90 | 1.20 | 0.0472 | 88 | 410 | 0.06 | 1740 |

| SFF-F100 | 100 | 1.30 | 0.0512 | 89 | 360 | 0.05 | 2000 |

SFF-1: Pleated stainless steel 3um sintered fiber cartridge with two reinforced rings outside

SFF-2: Stainless steel sintered flat filter cartridge with flange and center flat handle welded together

SFF-3: Pleated stainless steel sintered fiber cartridge with improved filter efficiency for dust removal

SFF-4: Stainless steel pleated sintered filter cartridge with flange and outer support rings

SFF-5: Stainless steel fiber sintered filter with outer support belts for automatic self cleaning

SFF-6: Stainless steel fiber sintered filter element used for ammonia filtration

SFF-7: Pleated stainless steel sintered fiber cartridge for natural gas filtration with high dirt-holding capacity

SFF-8: SS316L sintered fiber felt for high temperature of dust collection industry

SFF-9: Quality flat stainless steel sintered fiber cartridges for hot gas filtration

SFF-10: Sintered fiber felt in FeCrAl can resist high temperature up to 1100℃

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Related Products

Products

Request A Quote

Complete our interactive form to receive a custom quote based on your needs.